Control cable - Home decoration, is hard wire or soft wire better?

Comparison of flexible and rigid wires:

1. For home wiring, after flexible wires are run through conduits, electricians generally cannot achieve standard specifications in lamp holders or switch boxes. According to electrical installation standards, flexible wire joints need to be crimped or welded. This indicates that rigid wires are better.

2. Flexible wires have thin wire diameters and unreliable insulation materials, making them prone to aging and damage. Even if used, they are only suitable for limited use in connecting chandeliers and other electrical appliances, and are not suitable for use in fixed long-distance lines.

3. From a price perspective, due to the significantly higher labor and material costs of manufacturing stranded wires, the cost is naturally higher, and therefore there is no price advantage. Single-core wires are relatively cheaper.

In summary, rigid wires are clearly better. However, whether it's rigid or flexible wires, they will definitely be used in home decoration. Just remember that single-core rigid wires are better as main lines. Of course, it still depends on personal preference, as long as it doesn't affect future life.

In home decoration, is it better to use flexible or rigid wires?

1. First, what are rigid wires and flexible wires?

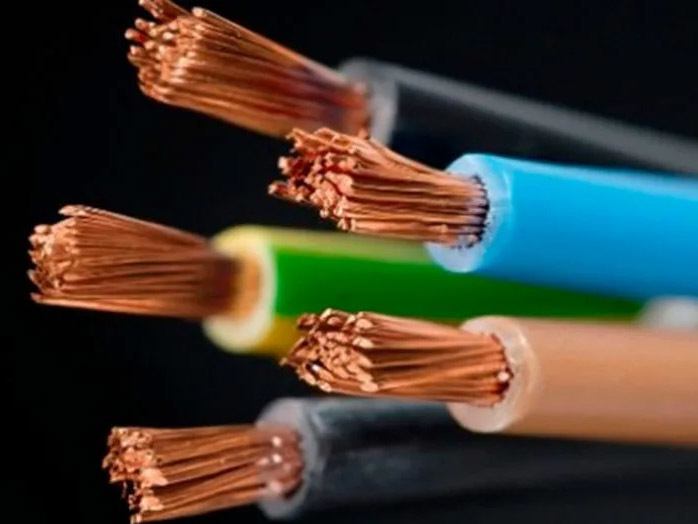

Rigid wire: A single conductive solid metal wire with a diameter of 1 mm or more, with higher hardness than flexible wire.

Flexible wire: A wire made of multiple strands of conductive solid metal wires with a diameter of less than 1 mm, twisted together.

2. What are their respective advantages and disadvantages?

Rigid wire: Low price, high tensile strength, high corrosion resistance, low fatigue resistance, high scrap recycling rate.

Flexible wire: Higher price, lower tensile strength, lower corrosion resistance, high fatigue resistance, low scrap recycling rate.

In general, rigid wires are still better. Flexible wires that have burnt out at the joints usually do so because each copper wire is too thin, easily damaged and oxidized, and the power distribution and heat conduction are uneven, causing the copper wires to burn out easily. Therefore, rigid wires are better in terms of durability, and they are easy to install in conduits, inexpensive, and quick to install. Moreover, flexible wires are currently more complex to manufacture due to their multi-wire metal composition, resulting in higher costs and no significant price advantage, so rigid wires are still preferable.

The advantages and disadvantages of flexible and rigid wires also determine their uses and locations. Rigid wires are generally used for embedding in walls and underground as main lines; flexible wires are generally used for the power connection lines of home appliances and equipment. There is no difference in which is better or worse, only which is suitable for which location. Therefore, you can choose between rigid and flexible wires according to the location of the decoration.

Tag:

Recommended News

Methods for testing the insulation strength of insulated wires and cables

Distinguishing between power cables and control cables requires attention to the following points

Xingzhou Cable explains the difference between flame-retardant cables and fire-resistant cables