Product

Contact Us

Hotline: 400-6019552

Tel & Phone:

+860317-2653118 / +8613903171615

Fax: +860317-2653866

Email: xingzhou118@126.com

Add: South of Jinhua Road, Renqiu Economic Development Zone, Hebei Province, China

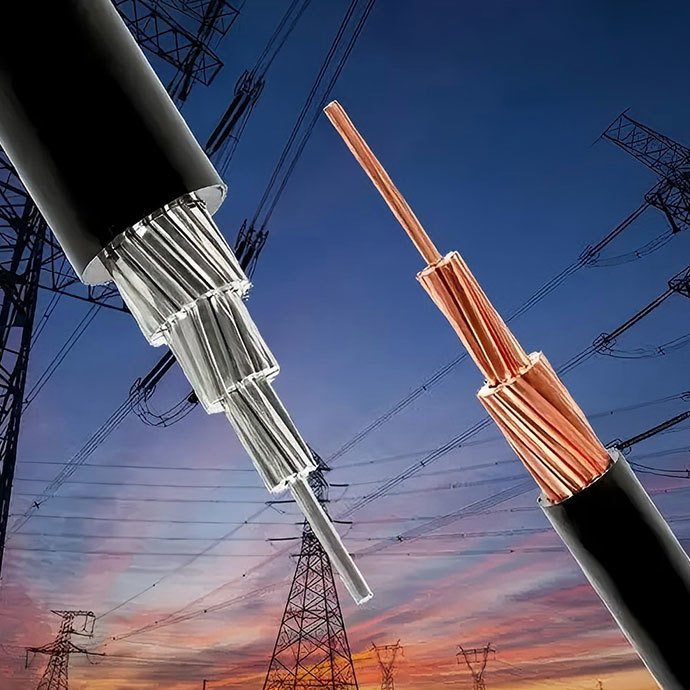

Aluminum alloy cable

Keywords:

Category:

- Product Description

-

Product Introduction

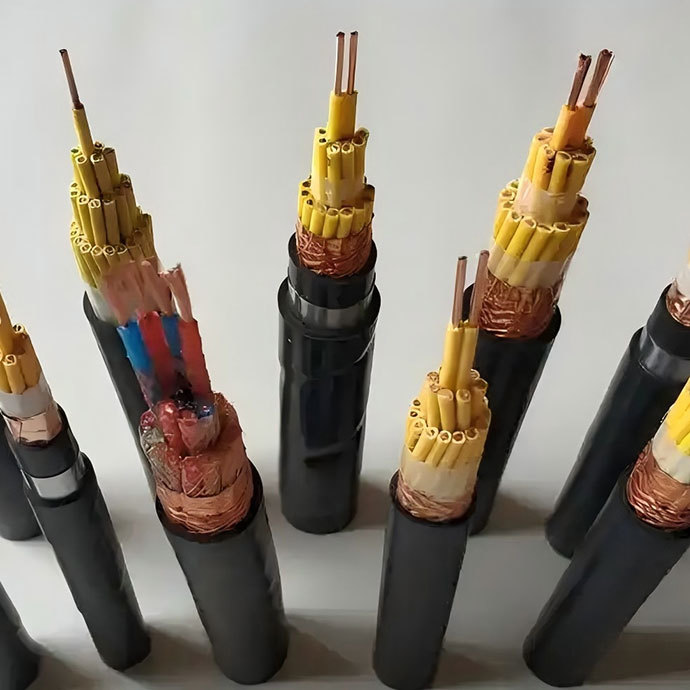

Aluminum alloy cable is a new type of power cable that uses AA8030 series aluminum alloy material as the conductor, possessing the following significant characteristics:

Electrical Conductivity and Current-carrying Capacity: The electrical conductivity of aluminum alloy cables is approximately 61.8% IACS. Although lower than pure copper cables, their conductivity can reach 100% IACS in the annealed state. Under the same current-carrying capacity conditions, the weight of aluminum alloy cables is about half that of copper cables, which helps reduce installation costs and minimizes wear and tear on equipment and cables, while also increasing efficiency in power transmission due to reduced energy losses compared to some other alternatives over long distances under heavy loads, ensuring stable and reliable performance even in demanding environments, which is crucial for modern electrical grids and infrastructure projects, allowing for greater flexibility in design and deployment, ultimately contributing to a more sustainable and cost-effective energy solution for both commercial and industrial applications across various sectors, including renewable energy systems and smart grid initiatives, as well as traditional power distribution networks, which benefit from the enhanced durability and longevity of these cables, making them a preferred choice for many engineers and project managers seeking innovative and reliable solutions for their electrical needs, aligning with global efforts to improve energy efficiency and reduce environmental impact through advanced material science and engineering practices. Moreover, the lightweight nature simplifies handling and transportation, further streamlining the overall construction process and leading to quicker project completion times, thus enhancing overall operational efficiency and reducing labor requirements on site, which provides significant advantages in large-scale installations where minimizing overheads and optimizing workflows are paramount for achieving desired project outcomes within budget constraints and tight deadlines, thereby solidifying its position as a competitive and viable alternative in the evolving landscape of electrical infrastructure development globally and fostering greater adoption of sustainable technologies.

Creep Performance and Mechanical Properties: The creep resistance of aluminum alloy cables has been significantly improved, comparable to copper core cables, which reduces the risk of joint loosening and increased contact resistance caused by creep. Furthermore, aluminum alloy cables have higher tensile strength and elongation, providing greater safety and reliability in various applications, and their enhanced mechanical properties contribute to longer service life and reduced maintenance requirements, which translates into lower operational costs over the lifespan of the cable system, making them an economically attractive option for large-scale projects, while also offering improved performance under thermal cycling and mechanical stress, ensuring stable operation in diverse environmental conditions and demanding industrial settings where robust and durable electrical infrastructure is critical for uninterrupted power supply and operational efficiency, further enhancing their appeal as a reliable alternative to traditional copper cables in modern electrical systems, and allowing for greater flexibility in installation methods due to their lighter weight and improved handling characteristics during deployment in complex routing scenarios, which is beneficial for optimizing construction timelines and resource allocation, thereby contributing to overall project success and sustainability initiatives in the power transmission and distribution sectors.

Connection Performance: The connection performance of aluminum alloy cables is superior to traditional aluminum cables, especially in terms of elasticity. Their recovery force is about 40% lower than that of copper cables, which makes tight connection of cable terminals easier and enhances the overall connection stability, ensuring reliable long-term performance and reducing the risk of failures at connection points, which is a critical factor for maintaining uninterrupted power supply and operational efficiency in various electrical systems, from residential buildings to large industrial complexes and utility grids, where robust and durable connections are essential for safety and reliability, contributing to a more stable and efficient electrical infrastructure, and making them a preferred choice for modern installations where ease of termination and secure electrical contact are paramount for optimizing system performance and minimizing maintenance requirements over time, thereby providing significant advantages in terms of installation speed and overall cost-effectiveness compared to other cabling solutions, which further solidifies their position as an innovative and practical alternative in the evolving landscape of power transmission and distribution technologies globally and fostering greater adoption of sustainable and high-performance materials in the industry.

Corrosion Resistance: Aluminum alloy cables possess excellent anti-corrosion properties. The self-protective oxide layer formed on their surface when interacting with the atmosphere at room temperature effectively resists further corrosion of the internal metal, extending the lifespan of the cables and ensuring stable performance even in harsh environmental conditions where exposure to moisture, chemicals, or pollutants might typically degrade other materials over time, which significantly reduces maintenance costs and replacement frequencies, thereby offering a more durable and reliable solution for long-term power transmission and distribution applications, and contributing to overall system integrity and safety in demanding industrial or outdoor settings, where resistance to environmental stressors is crucial for uninterrupted operation and minimal downtime, further enhancing their appeal as a sustainable and cost-effective alternative to traditional copper cables in modern electrical infrastructure projects globally and promoting greater adoption of advanced material science in the pursuit of more resilient and efficient energy systems, aligning with global efforts to improve infrastructure longevity and reduce environmental impact through innovative material engineering practices.

Economic Benefits: Aluminum alloy cables demonstrate significant advantages in both performance and economy. Under the same current transmission conditions, the weight of aluminum alloy cables is only 45.6% of copper's. Furthermore, through unique compact compression technology, the compaction factor of aluminum alloy cables can be increased to 0.95, whereas copper cables only achieve 0.80 after a single compression, which leads to a smaller overall cable diameter for the same current-carrying capacity, resulting in reduced material usage, lower installation costs due to lighter weight and easier handling, and increased conduit fill capacity, optimizing space utilization in ducts and trays. This economic benefit, combined with their superior technical characteristics, makes them a highly competitive and attractive option for various electrical projects, from commercial buildings to large-scale industrial plants and utility infrastructure, where cost-effectiveness and efficiency are paramount for achieving project success and maximizing return on investment, thereby positioning them as a strategic choice in the evolving landscape of power distribution and transmission technologies and fostering greater adoption of sustainable and economically viable solutions in the industry, aligning with global efforts to optimize resource allocation and minimize environmental footprint through advanced engineering practices and material innovation.

In summary, aluminum alloy cables, with their excellent electrical performance, mechanical properties, connection performance, and corrosion resistance, have been widely applied in various fields and are gradually becoming an important choice in the power industry.

Product Inquiry

Note: Please leave your contact information, our professionals will contact you as soon as possible!